The role of hydraulic or pneumatic system in mechanical engineering is mainly to increase the force by changing the pressure. The Body Casing and Fittings, valve body and other accessories are a major part. According to the pressure and the use of the environment and conditions, different mechanical manufacturing methods are used, such as casting, forging, etc. Medium and low pressure specifications of the valve body usually adopts the casting method (precision casting, gravity casting, low pressure casting) process production, and the valve core and valve seat sealing ring together to form a seal can effectively withstand the medium (water, gas, oil) pressure, the material of the valve body according to different process media, choose different metal materials, Commonly used materials are: aluminum alloy, cast iron, cast steel, stainless steel, carbon steel and so on!

Product Parameter (Specification)

|

Production technology |

material |

advantage |

Notes |

|

(investment) precision casting |

AISI 304/CF8M |

Strong corrosion resistance. Precise size |

(medium temperature wax) silica sol process |

|

WCB |

The price is economical/widely applicable |

(low temperature wax) water glass process |

|

|

Gravity casting/low pressure casting |

Aluminium alloy |

Lightweight, price economy |

(steel mold) gravity or low pressure pouring |

|

Shell casting |

Copper alloy |

Improve quality and application performance |

Short cycle, high efficiency |

|

Sand casting |

QT400-15 QT400-18 QT450-10 QT500-7 QT600-3 QT700-2 |

Complex structure and large volume |

Suitable for large machinery and equipment |

|

HT100/HT150 HT200/HT250 |

|||

|

Sand casting (cast steel) |

WC1, WCB, ZG25, 20, 25, 30 and low alloy structural steel 16Mn |

Product Feature And Application

Hydraulic and pneumatic valve body application equipment or industry:

Metallurgy, construction machinery, all kinds of processing machine tools, agriculture, energy industry, transportation and shipping industry, special industry, general machinery, etc.

There are many kinds of valve body classification, according to the function of points, control mode points, spool structure form points, installation mode points.

According to the function, can be divided into three kinds of pressure control valve, flow control valve, direction control valve!

In construction machinery hydraulic and pneumatic system is an indispensable component, often used in the operation of construction machinery, control part. The main components are pressure gauge, oil pump, valve body, joint, tubing, cylinder and so on.

Product Details

Our current production process: gravity casting, aluminum die casting + machining + surface treatment (conventional shot blasting, oxidation, plastic spraying, etc.)

Low pressure casting + machining + surface treatment (conventional shot blasting, oxidation, plastic spraying, etc.)

(investment) Precision casting + machining + surface treatment (conventional pickling, passivation, spraying, etc.)

Cast iron, cast steel: blank + machining + surface treatment (conventional pickling, passivation, spraying, etc.)

The material is aluminum alloy, conventional grade: ZL102 and ASTM A356.2

Made of stainless steel, regular grade: AINI301/304/CF8M/CF8

Material is copper, conventional grade: lead-free copper HDT-2 (HBi60-0.8) tin brass C46500/C46400

Sand casting (cast iron) : HT200/HT250

Sand casting (cast steel) : WC1, WCB, WCC, ZG25, etc

Surface treatment: shot blasting, pickling, spraying, oxidation, etc

Surface requirements: according to and meet customer needs!

Product Qualification Product certification and qualification

Supporting products:

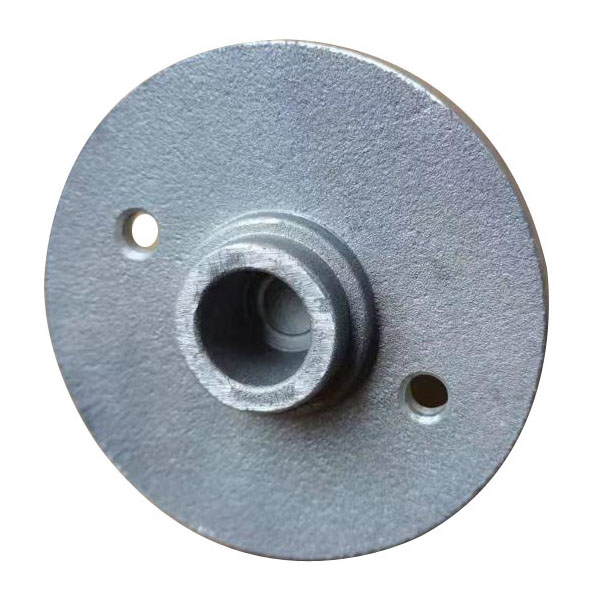

Product pictures

Deliver,Shipping And Serving

Delivery of transportation and services

Transportation method: sea freight, railway, air freight

Packaging method: pallet (plywood or fumigated wood), wooden box+lid+cardboard box+corner protection+PE film

Delivery method: FOB Ningbo or Shanghai

Workshop picture: (machining equipment, pouring, die casting workshop)